Share to

Chemical anchor

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product Description

-

Product Description:

Consisting of metal parts (screw, flat washers, nuts) and chemical tubes.

Metal parts are available in 5.8 grade steel, 8.8 grade steel, 304 (A2-70)/316 (A4-80) stainless steel and other materials.

Metal (except stainless steel) part of the surface treatment are:

1、Electro-galvanised (zinc layer thickness >5um), used in ordinary environment;

2、Hot dip galvanising (zinc layer thickness >50 um), used in corrosive environments;

The chemical agent consists of modified vinyl resin, quartz sand and curing agent.Product Applications:

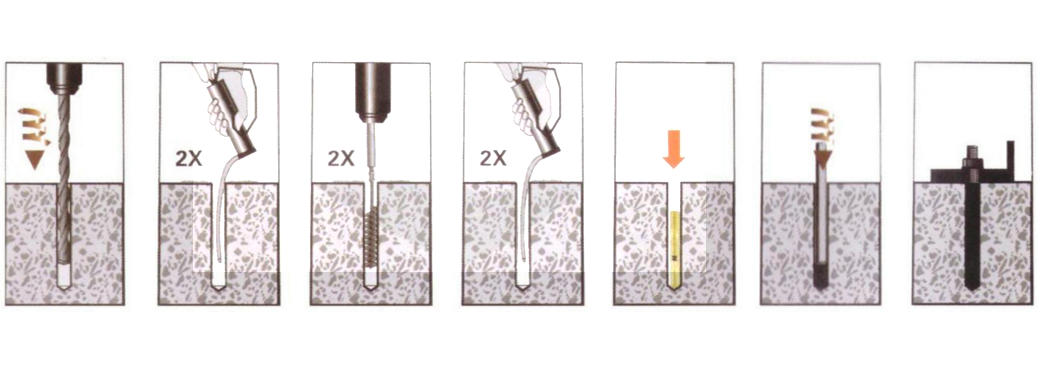

Applied to non-cracked concrete, natural stone and other substrates, small spacing, small margins of the structural components of the fixed or equipment installation of high-strength chemical anchors in the high loads, vibration loads have a stable, excellent anchorage performance.Operation process:

1. Drill holes of appropriate diameter and depth using a straight hole drill bit

2. Use a dust blower to blow dust into the holes more than twice

3. Use the brush to clean the dust on the wall of the hole more than 2 times

4. Use the soot blower to blow dust into the hole until no dust overflows from the hole

5. Put in chemical anchor bolts

6. Use the torque drill to screw in the high strength chemical anchor bolt to complete the anchoring

★Chemical reaction times

Condensation schedule: Substrate temperature Hardening time -5°C~0°c 5h 0°C~10°c 1h 10°C~20°c 30min ≥20°c 20min ★Product specifications and technical parameter

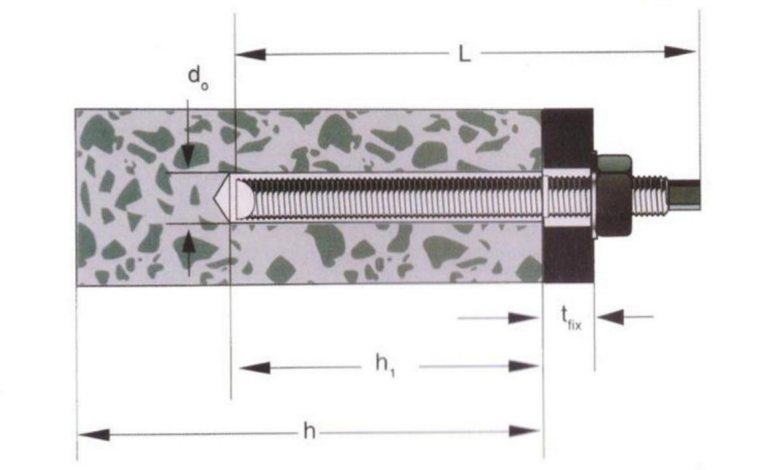

Product Specification Drill diameter d0(mm) Drilling depth h1(mm) Maximum anchor thickness tfix(mm) Minimum substrate thickness h(mm) Overall screw length L(mm) M8*110 10 80 15 140 110 M10*130 12 90 20 160 130 M12*160 14 110 25 210 160 M16*190 18 125 35 210 190 M20*260 25 170 65 340 260 M24*300 28 210 65 370 300 M30*380 35 270 70 540 380 ★Table of basic design parameters

Product Model M8 M10 M12 M16 M20 M24 M30 Tensile design reference value on C30 concrete Level 5.8 9.3 13.8 19.8 30.9 52.4 87.5 113.6 Level 8.8 12.4 16.8 22.9 34.5 58.8 87.5 133.6 A2-70 11.8 15.3 20.8 32.3 55.8 87.5 133.6 A4-80 12.4 16.8 22.9 34.5 55.8 87.5 133.6 Shear design reference value on C30 concrete Level 5.8 6.8 10.5 14.5 27.8 45.5 65.5 121.3 Level 8.8 8.3 13.1 19.0 32.3 55.2 82.0 132.6 A2-70 7.9 12.6 18.3 29.0 51.4 75.5 127.6 A4-80 8.3 13.1 19.0 32.3 55.2 82.0 132.6

Chemical anchor

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Chemical anchor

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!