Share to

Epoxy anchoring adhesive

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product Description

-

Application:

·Steel Structure

·Contact rail anchorage in tunnels

·Contact rail anchoring in bridges

·Brackets

·Pipes

·Cable ductsAdvantages:

·Seismic and fatigue resistance for 2 million times.

·With G 50728 "Technical specification for safety appraisal of engineering structural reinforcement materials" Long-term stress resistance certification report.

·Excellent bonding performance even under high temperature.

·Safe, environmentally friendly and non-toxic, passed the non-toxic test of CIRC.

·Non-expansion stress, can be installed under smaller side and spacing conditions.

·Has seismic performance, through the building research institute low week repeated tensile action, seismic performance test.Features:

·Resistant to moisture and heat aging, freezing and thawing.

·Resistant to acid, alkali and smoke.

·Burning performance class IB.

·Flexural strength, tensile strength class A.Material:

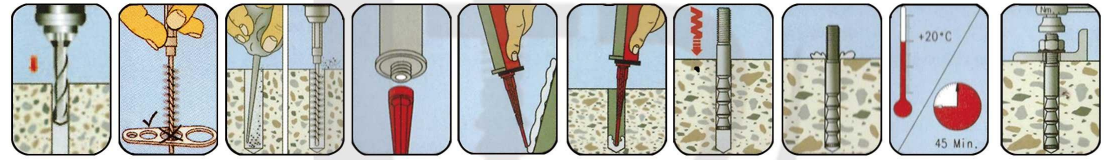

·Mixer installed after the head of the glue about 10cm can not be used (at this time the gel is not mixed evenly) need to support the use of a special rebar gun is not a one-time use of the rebar glue can be replaced after the mixing head of the second use.Curing time

Substrate temperature Initial setting time Curing time -10℃~-5℃ 180min 8D -5℃~-0° 120min 7D 0℃~-10℃ 60min 6D 10℃~-25℃ 40min 4D 25℃~-40℃ 20min 2D >40℃ 10min 1D Installation steps

Rubber Usage Chart

Anchor bolt type Hole Diameter(mm) Buried depth(mm) Number of holes available for each rubber M12×160 14 110 28 M16×190 18 125 15 M20×260 25 170 6 M24×300 28 210 4 M30×380 35 280 2 Technical parameters

Testing items Testing basis Technical index (Class I rubber) Test results Individual assessment Grade A Split tensile strength, MPa GB50728-2011 ≥8.5 18.23 meets Flexural strength GB/T2567-2021

GB 50728-2011

Article 4.2≥50, and shall not be cracked damage 82.9 and shall not be damaged in a crumbly manner meets Compressive strength ≥60 101.6 meets Steel to steel tensile shear strength, standard value GB/T 7124-2008 ≥10 15.2 meets Bond strength between ribbed steel bar and concrete under end pull-out condition c30 $25 L=150mm GB 50728-2011 Appendix K ≥11 14.0 meets c60 $25 L=125m ≥17 20.2 meets Steel-to-steel impact peeling length, mm GB 50728-2011 Appendix F ≤25 0 (no cracking) meets Heat distortion temperature,℃ B method with bending stress of 0.45 MPa GB/T 1634.2-2019 ≥65 67.4 meets Non-volatile matter content,% GB 50728-2011 Appendix H

≥99 99.6 meets Note:The table data is for reference only, the specific dosage is decided according to the working conditions.

Epoxy anchoring adhesive

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Epoxy anchoring adhesive

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!