Share to

Epoxy anchoring adhesive TD400

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product Description

-

Presentation:

·It meets the requirements of the current national standards GB50367 "Design Code for Concrete Structural Reinforcement", GB50728 "Technical Specification for Safety Identification of Engineering Structural Reinforcement Materials" and G850550 "Building Structure Reinforcement Engineering Construction Quality Acceptance Specification" 1 class A class rubber index requirements.

·Has a high temperature resistance test, seismic anti-fatigue 2 million times, non-toxic, cracked concrete tensile, shear bearing capacity certification report.

·Colloid shrinkage is low, can be used for large-diameter reinforcement.

·Two-component anchoring adhesive independently in two hoses, when used by injection glue gun will be two components in the mixer fully mixed.Advantages:

·Seismic and fatigue resistance for 2 million times.

·With G 50728 "Technical specification for safety appraisal of engineering structural reinforcement materials" Long-term stress resistance certification report.

·Excellent bonding performance even under high temperature.

·Safe, environmentally friendly and non-toxic, passed the non-toxic test of CIRC.

·Non-expansion stress, can be installed under smaller side and spacing conditions.

·Has seismic performance, through the building research institute low week repeated tensile action, seismic performance test.Application:

·Steel Structure

·Contact rail anchorage in tunnels

·Contact rail anchoring in bridges

·Brackets

·Pipes

·Cable ducts

·Balustrade

·Wooden structureFeatures:

·Resistant to moisture and heat aging, freezing and thawing.

·Resistant to acid, alkali and smoke.

·Burning performance class IB.

·Flexural strength, tensile strength class A.Caveat:

·Resistant to moisture and heat aging, freezing and thawing.

·Resistance to acid, alkali and smoke.

·Burning performance HB grade.

·Flexural strength, tensile strength A grade.Curing time

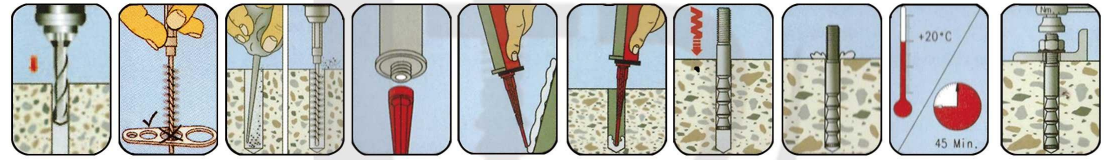

Substrate temperature Initial setting time Curing time -10℃~-5℃ 180min 8D -5℃~-0° 120min 7D 0℃~-10℃ 60min 6D 10℃~-25℃ 40min 4D 25℃~-40℃ 20min 2D >40℃ 10min 1D Installation steps

Rubber Usage Chart

Anchor bolt type Hole Diameter(mm) Buried depth(mm) Number of holes available for each rubber M12×160 14 110 28 M16×190 18 125 15 M20×260 25 170 6 M24×300 28 210 4 M30×380 35 280 2 Technical parameters

Testing items Testing basis Technical index (Class I rubber) Test results Individual assessment Grade A Split tensile strength, MPa GB50728-2011 ≥8.5 18.23 meets Flexural strength GB/T2567-2021

GB 50728-2011

Article 4.2≥50, and shall not be cracked damage 82.9 and shall not be damaged in a crumbly manner meets Compressive strength ≥60 101.6 meets Steel to steel tensile shear strength, standard value GB/T 7124-2008 ≥10 15.2 meets Bond strength between ribbed steel bar and concrete under end pull-out condition c30 $25 L=150mm GB 50728-2011 Appendix K ≥11 14.0 meets c60 $25 L=125m ≥17 20.2 meets Steel-to-steel impact peeling length, mm GB 50728-2011 Appendix F ≤25 0 (no cracking) meets Heat distortion temperature,℃ B method with bending stress of 0.45 MPa GB/T 1634.2-2019 ≥65 67.4 meets Non-volatile matter content,% GB 50728-2011 Appendix H

≥99 99.6 meets Note:The table data is for reference only, the specific dosage is decided according to the working conditions.

Epoxy anchoring adhesive TD400

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Epoxy anchoring adhesive TD400

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!